The biggest task of this century is to reduce the level of CO2 in the atmosphere, to slow down climate change.

One key technology is to capture any emitted CO2 to prevent it from affecting the climate. But how can we store this captured CO2 in a safe and permanent manner?

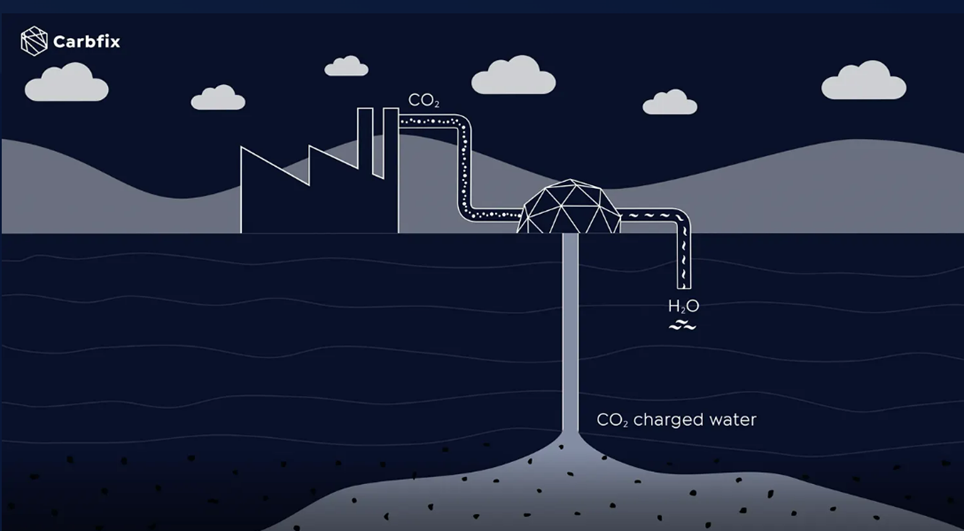

The Carbfix-process:

The growth of trees and vegetation is not the only way by which carbon can be naturally captured from the atmosphere and stored in solid form. Vast quantities of carbon have also been naturally stored in solid form in rocks for billions of years.

In Iceland, a method has been developed whereby CO2 is captured and turned into stone, deep underground. This might sound like magic, but it is actually one of the Earth’s natural ways of getting rid of excess CO2 from the atmosphere. Thus, CO2 from the atmosphere has been turned into stone by reaction with metals that are present in certain rocks for billions of years. The best kind of rocks for this process are volcanic rocks, such as basalt and peridotite, which contain a lot of metals needed for this reaction. In nature, this is a slow process – too slow to prevent the global warming that is currently affecting the Earth.

Carbfix, however, imitates and accelerates these natural processes, by bringing CO2 into contact with reactive rock formations, such as basalts, to form stables minerals providing a permanent and safe carbon sink.

The Carbfix process thereby captures and permanently removes CO2 from the atmosphere. In the Carbfix process the CO2 is first dissolved in water, the same way a soda machine makes sparkling water. The water with the dissolved CO2 is then pumped deep into the ground. If the sparkling water is pumped into the right kinds of rocks in the right way, the rocks release metals that mix with the CO2 in the water and the CO2 is turned into stone. This process safely and permanently removes the CO2 from the atmosphere, since the minerals that form remain stable for millennia.

In just seven years, Carbfix was transformed from an idea on paper to a fully operational, cost-effective and environmentally friendly industrial process to capture not only CO2 but also H2S from emission sources and permanently store it as rock in the subsurface.

Furthermore, the technology is versatile enough to be adapted to other carbon emitting industries, such as steel, iron and cement production and several pilot projects are already underway with the aim of adapting the technology to other industries and other circumstances.

You are welcome to find out more at www.carbfix.com